We love paper and we adore letterpress. In fact, we’re a little obsessed and we wouldn’t have it any other way! Creating unique, luxurious paper goods brings us great joy!

About Hubbub Paper Co

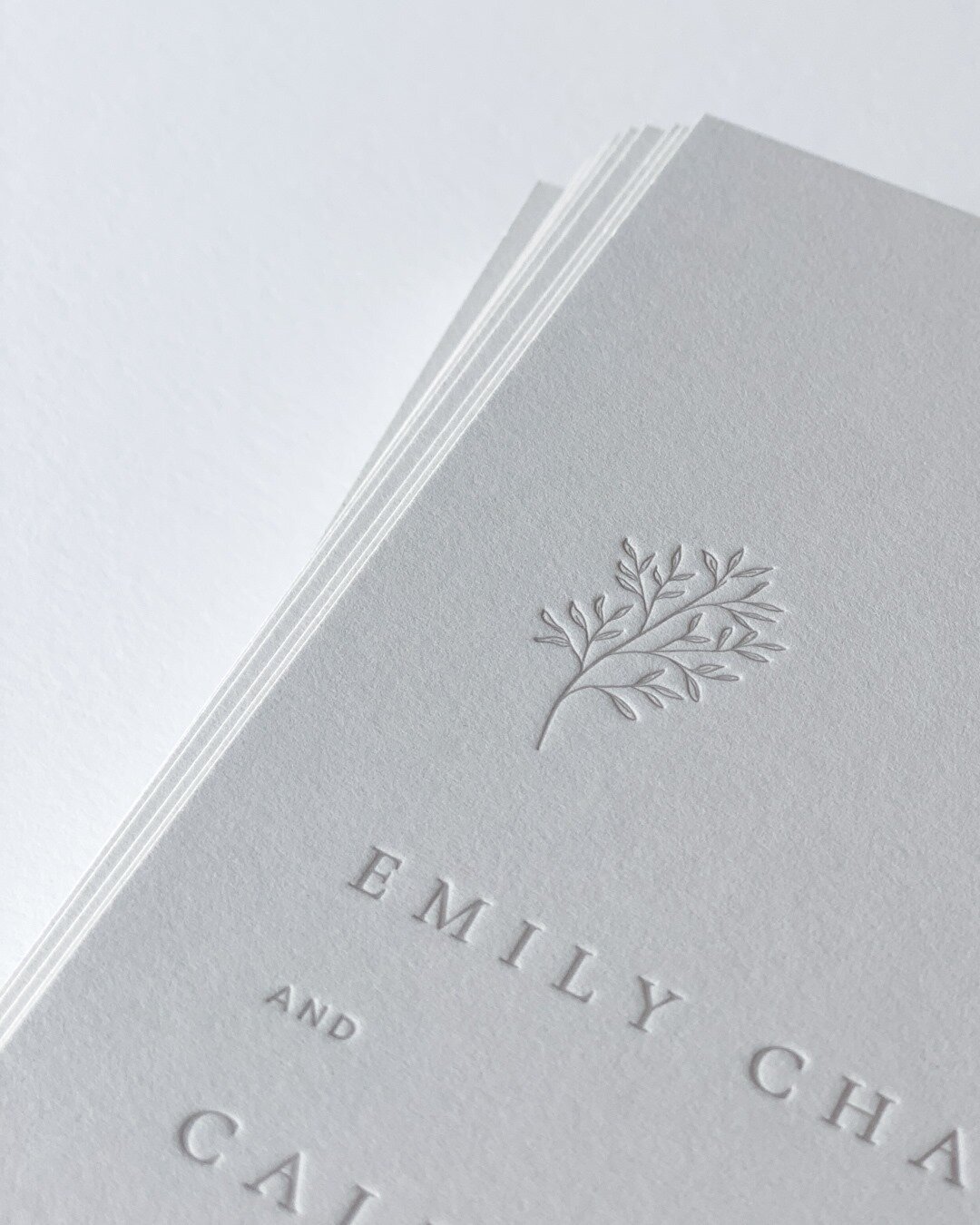

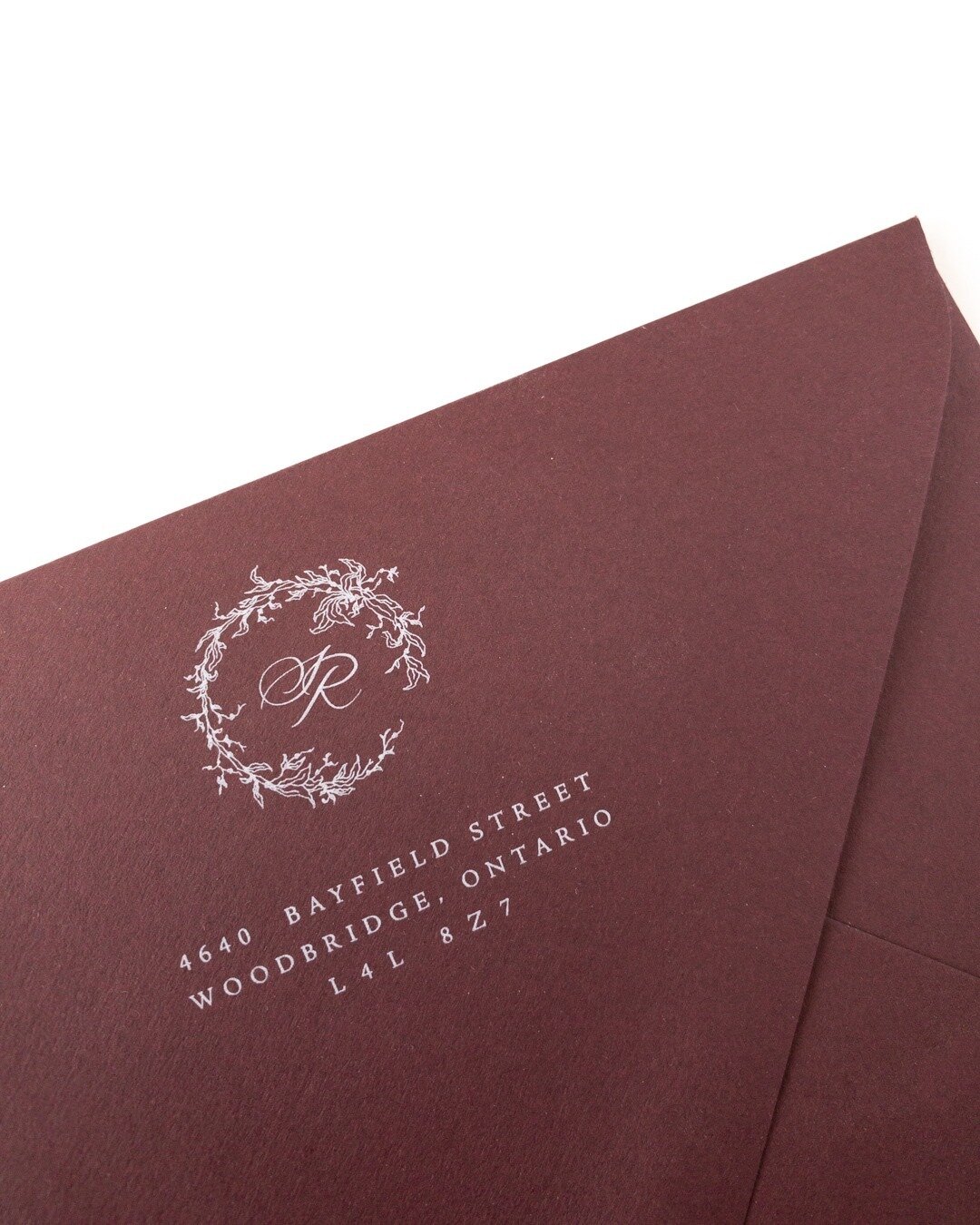

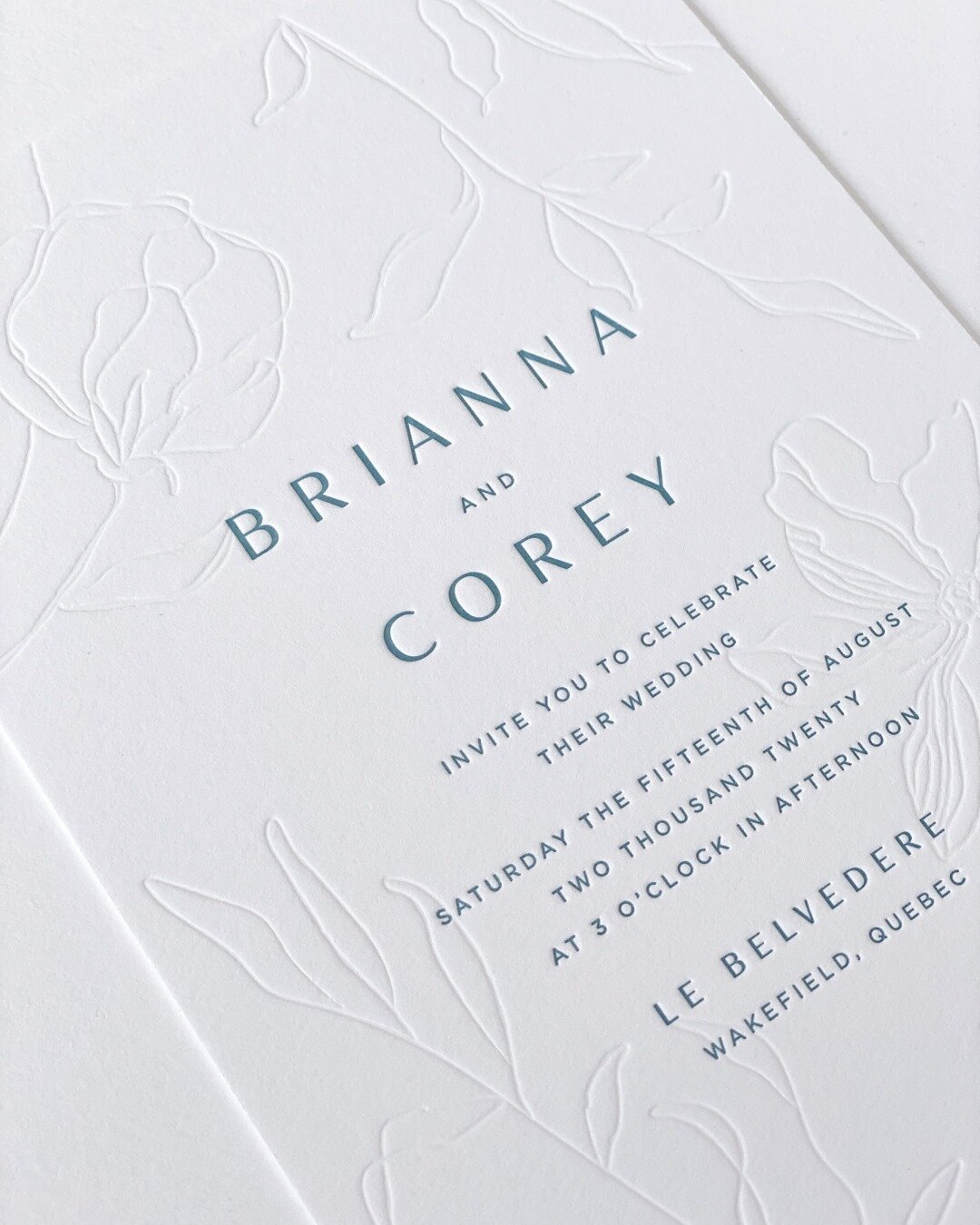

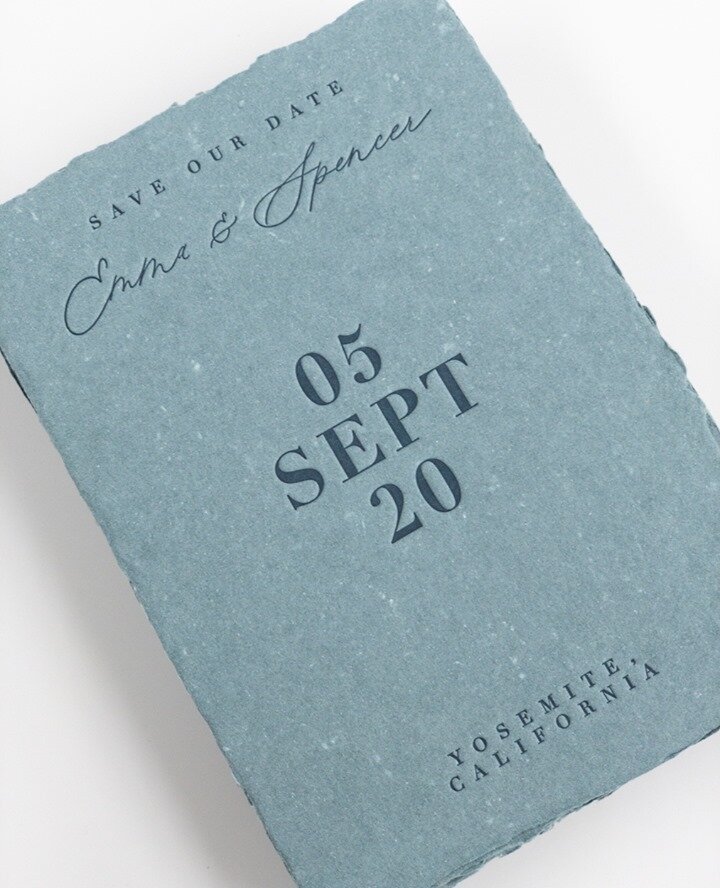

Founded in 2015 by husband and wife team Sibylle and Steve, Hubbub Paper Co is a boutique letterpress studio specializing in bespoke custom stationery. From elegant wedding and event suites to sophisticated business stationery, we bring our obsession to quality and craftsmanship to every project.

We love the mix of old and new that letterpress offers. It has a unique, timeless quality that isn’t readily found in other printing methods. There is something beautiful and a little romantic about the process and finished pieces.

Meet Our Team

Sibylle Cox

Presswoman & Designer

Steve Cox

Pre-press & Studio Manager

Portfolio

Our Recent Work

We’d love to work with you!